Products

The company's main products include 1050 ° C and 650 ° C asbestos free high-temperature resistant calcium silicate insulation products

Provide thoughtful service and high-quality products

Date:2023-09-22 10:53

Category:Products

Application area:

high-density non-stick alumina calcium silicate board is a kind of non-asbestos refractory material with high strength , lowshrinkage and low thermal conductivity . There are mainly two types which are glass fiber reinforced boards and carbon fiberreinforced boards . The bulk density is generally 800-1000kg / m , and the highest service temperature is 1000'C NR unique fiberdispersion technology makes the fibers be able to evenly distributed in the calcium silicate matrix to greatly improve the hightemperature resistance ability and thermal shock resistance ability

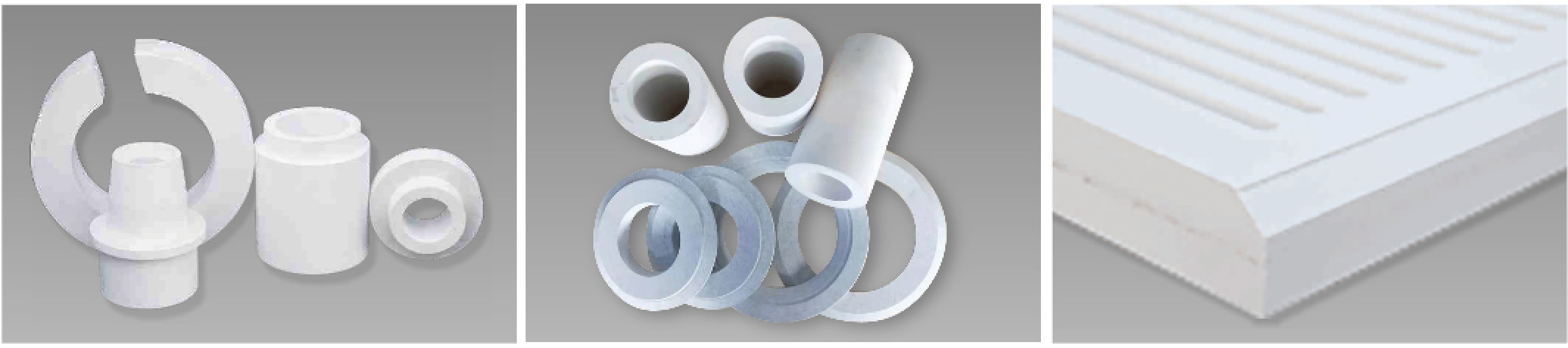

high-density non-stick alumina calcium silicate board has good thermal shock stability , excellent mechanical processingrerformance , and is non-stick aluminum , can be easily processed into a variety of precision parts , mainly suitable for non-ferrousmetallurgy industry , especially for LPDC , HPDC , CPC and gravity casting related equipment , such as hot top ring , transfer platecover plate , gate , nozzle , casting box , flow groove , sleeve and so on

| FEATURES | |

| Heat-resistant at high temperature | Excellent mechanical strength |

| Non asbestos | Thermal shock resistance |

| Outstanding thermal insulation performance | Easy to shape and install |

| Non-stick aluminum | |

| TYPICAL SIZES | ||

| Length * Width * Thickness | 1200mm(L)*1200mm(w)*20~120mm(T) | 1200mm(L)*600mm(w)*20~120mm(T) |

| TECHNICAL DATE | |||

| Product type | C board (carbon fiber reinforced) | T-board (glass fiber reinforced) | |

| Density | kg/m³ | 750-850 | 800-900 |

| Classification temperature | °C | 1000 | 1000 |

| Service temperature | °C | 850 | 850 |

| Bending strength | Mpa | 8 min | 8 min |

| Cold compressive strength | Mpa | 17 min | 17 min |

| Thermal Conductivity | |||

| 200°C | W / m.K | 0.13 | 0.13 |

| 400°C | W / m.K | 0.15 | 0.15 |

| 500°C | W / m.K | 0.15 | 0.15 |

| Linear Shrinkage @ 850C * 24h | |||

| Length or width direction | % | 0.31 | 0.31 |

| Thickness direction | % | 1.61 | 16.1 |

| Production Sizes | |||

| Length | mm | 1200(±2) | 1200(±2) |

| Width | mm | 1200(±2) | 1200(±2) |

| Thickness | mm | 20-120(±1) | 20-120(±1) |